PCB Capabilities

Kitting & Materials Logistics

As part of our “One Stop Shop service” PSL can provide a comprehensive material supply package covering every aspect of component procurement, from hard-to-source one line items to full kit supply including bare boards...

Read more

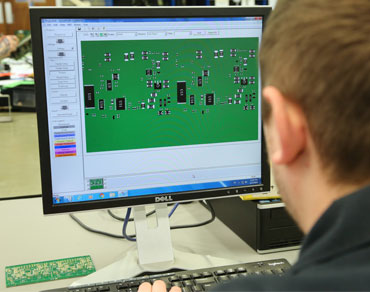

ENGINEERING

The hub of any production facility is its production engineering department At PSL, production engineers are available to generate all aspects of the process paperwork, and tooling ensuring that the highest levels of quality...

Read more

Design for Manufacture

The engineering staff at PSL can review existing or new products to optimize the production process, which in turn provides our customers with the most cost effective solution to their manufacturing needs...

Read more

Controlled Storage

At PSL we have a 10,000 sq ft bonded storage facility, complete with all the processes required by cutting edge Electronic Assembly. We have a moisture control area to cope with the millions of customer-supplied components...

Read more

surface mount Assembly

Based on state-of-the-art placement equipment, screen printers and reflow ovens, PSL can provide solutions to a wide range of surface mount scenarios...

Read more

Hand Assembly

Our assembly operators have a vast experience in all forms of PCB and Unit assembly covering both commercial and military products. The workforce prides itself...

Read more

Flow Solder

One of the most important attributes of the modern day PWBA production factory is still Flow Solder. The Blundell wavesolder equipment used at the facility is capable of accommodating...

Read more

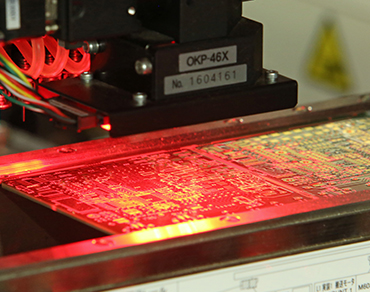

AOI

As a further aid to continuous quality improvement, PSL has added four Automatic Optical Inspection systems to its already impressive arsenal of equipment...

Read more

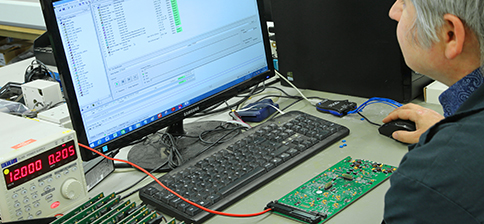

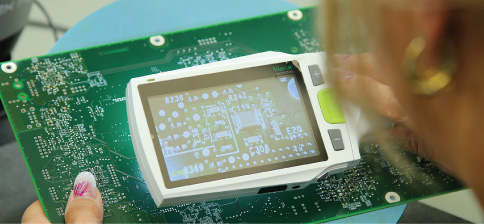

Test

Although we believe that our assembly processes provide the highest quality possible, we recognize that sometimes this is not enough. Customer perception is a very important aspect of the Contract Manufacturing Marketplace and a full test facility...

Read more

BGA Replacement

More and more design teams are taking advantage of the integration of function and reduced space requirement afforded by BGA packages. To this end, PSL can now offer a BGA placement and upgrade service for those customers...

Read more

Unit Assembly

In many instances, assembly of the PCB is only part of the process. For many of our customers we also amalgamate the PCB assembly into higher levels of product. This may include wiring, cabling and mechanical assembly...

Read morePCB Capabilities

Kitting & Materials Logistics

As part of our “One Stop Shop service” PSL can provide a comprehensive material supply package covering every aspect of component procurement, from hard-to-source one line items to full kit supply...

Due to our broad base links to the materials supply infrastructure PSL can source components quickly and cost-effectively for an extremely wide range of end uses.

Whether your need is for PCBs, reeled components, complex devices or just hard to find parts, the team at PSL can assist.

Engineering

The hub of any production facility is its production engineering department.

At PSL, production engineers are available to generate all aspects of the process paperwork, and tooling ensuring that the highest levels of quality and on-time delivery are met whilst endeavouring to maintain minimum cost.

We have the ability to generate all the process tools required for a wide range of customer needs from purely commercial to military applications, and our production engineering expertise ensures a fast but controlled response to both long and short term customer requirements.

Efficient tooling makes for efficient shopfloor processes and optimum product quality.

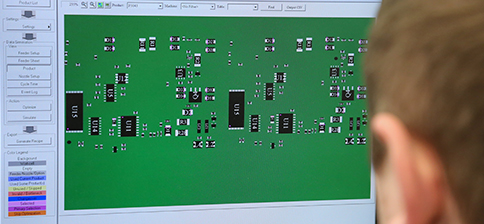

Design for Manufacture

The engineering staff at PSL can review existing or new products to optimize the production process, which in turn provides our customers with the most cost effective solution to their manufacturing needs...

Company personnel can convert existing through-hole assemblies into more state-of-the-art surface mount Assembly technology, again providing significant savings both in terms of cost and lead-time.

Irrespective of complexity, PSL can transform your new ideas into a cost effective addition to your product range. Is your product as easy to manufacture as the competitions? Here too we can help. Customer products can be assessed in term of ease of manufacture and recommendations made to ensure that all production activities are optimised.

Ease of manufacture goes hand in hand with fast reaction times and on time delivery. Small changes in layout or design can save you time and money by simplifying and speeding up the assembly process. PSL are experts at making these recommendations for our customers' advantage.

Controlled Storage

At PSL we have a 10,000 sq ft bonded storage facility, complete with all the processes required by cutting edge Electronic Assembly....

We have a moisture control area to cope with the millions of customer-supplied components awaiting assembly. We also have baking ovens and a vacuum sealer for any moisture sensitive devices. Our stores personnel are fully trained in component moisture sensitivity levels and keep records of time and temperatures of the components stored, if required.

Understanding the problems that may occur to components, and having adequate procedures in place to stop them happening, results in very high levels of first time pass rates on products tested at PSL or by the end customer.

All material is booked in using the customer-supplied BOM and any issues are passed on to the production manager where they can be resolved very quickly. This ensures the end customer always gets the quality products that they are expecting. Any shortages are identified and a shortage log is generated. This enables the production manager to liaise with the supplier or customer and to keep them updated on the production of their builds.

Free issued material is also controlled in this facility and customers are given their own locations, where the stock is controlled by the use of our cloud-based system. This allows remote access to the stock levels by the customer. Also, any returned kits are booked out and a record kept of the quantities returned to the customer.

We are very conscious of the costs of materials, and do all we can to make sure that once the material is here it is stored and handled within the correct parameters for the type of component that is to be stored.

surface mount Assembly

Based on state-of-the-art placement equipment, screen printers and reflow ovens, PSL can provide solutions to a wide range of surface mount scenarios...

Within our 9 lines we have a variety of pick-and-place machines, offering us complete flexibility of use, with sizes up to 1.5m in length on a single board and speeds of up to 140,000 placements per hour.

Surface mount, through hole / surface mount hybrids, fine pitch BGA, UBGA, Flexi, Flexi-Rigid, FR4, Ceramic and Metal substrate can be accommodated into our flexible manufacturing process.

Passive devices down to 01005, plus large fine pitch and BGA packages can be co-resident within the same assembly.

Front-end engineering provides the customer with hard copy verification that re-flow eutectics are within acceptable parameters and that components are not exposed to any form of detrimental thermal shock.

Process control is such that once the initial engineering work has been completed, the repeatability of parameters for on-going production batches is assured to as near as possible 100%.

Hand Assembly

Our assembly operators have a vast experience in all forms of PCB and Unit assembly covering both commercial and military products...

The workforce prides itself in its ability to provide extremely high levels of quality. This is achieved by the fact that each operator takes personal responsibility for attaining zero defects, and this coupled with a closed loop corrective action procedure that ensures any potential improvements to the assembly process are captured and implemented.

First off, and in-process inspection incorporating AOI ensures that manufacturing process errors are mimimized and that our high levels of quality are maintained.

PSL assembly operators can also action configuration changes, by way of modification, to existing products. These upgrades are of course to the same quality levels as any new assemblies.

FLOW SOLDER

One of the most important attributes of the modern day PWBA production factory is still Flow Solder...

The Blundell wavesolder equipment used at the facility is capable of accommodating conventional through hole assemblies as well as surface mount hybrids that conform to all aspects of ISO9001:2015.

Solder joint integrity and quality is recognised as one of the major cornerstones of any PCB based product and at PSL we pay great attention to detail in this area.

Appropriate levels of preventive maintenance ensure that equipment is performing at optimum efficiency.

Closed loop positive feedback from online quality control and test engineers maintain high levels of quality.

AOI

As a further aid to continuous quality improvement, PSL has added four Automatic Optical Inspection systems to its already impressive arsenal of equipment...

XY Data from any of the SMD placement machines can be fed to the AOI station and then used as a basis for a high speed SAKI BF-Voyager optical scan of the PCB assembly under review.

With its comprehensive, multi-level lighting and camera system, the MIRTEC can perform a wide range of inspection tasks with far greater levels of accuracy, speed and consistency than even the best human inspector.

Areas covered by the MIRTEC include:

- s/c detection

- dry joint/open circuit detection

- text recognition and hence component value/identity checks

- polarity/rotational checks

- component omission and placement accuracy checks

Because of the link to the surface mount assembly process, the AOI station can be almost instantaneously up to speed and on line, checking production of new products.

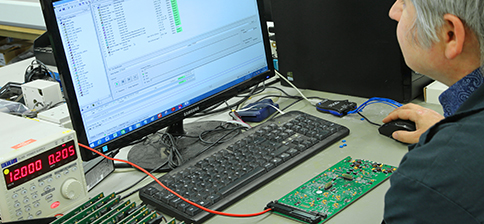

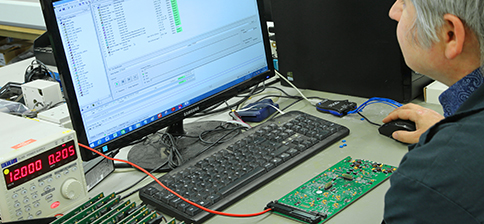

Test

Although we believe that our assembly processes provide the highest quality possible, we recognize that sometimes this is not enough. Customer perception is a very important aspect of the Contract Manufacturing Marketplace and a full test facility is available to support this...

We ensure that the testing process reflects the parameters and uses that the product will encounter in its working life as accurately as possible. This means every unit that leaves our facility will function to the specification laid down by the customer.

The test process can be PC-based or can utilize specific test equipment as specified by the customer.

Test results of all products are recorded and any failures correlated to be fed back into the assembly process via the corrective action system and ensure continuous improvement.

BGA Replacement

More and more design teams are taking advantage of the integration of function and reduced space requirement afforded by BGA packages. To this end, PSL can now offer a BGA placement and upgrade service for those customers who require this facility...

Using a PDR rework station PSL can now place, or replace, all forms of BGA footprint devices. The system ensures that both correct temperatures and eutectic curves are met when dealing with what can be expensive prototype or production parts.

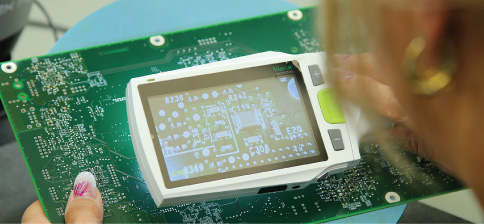

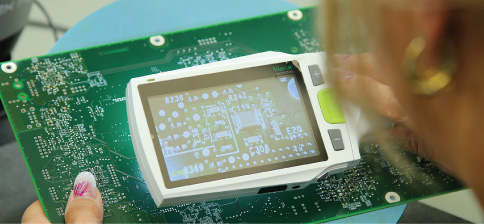

BGA Inspection

Once placement or rework has been carried out, PSL can then use its Ersascope inspection station to review the solder joints beneath the devices to ensure that the correct alignment and 'double drop' profiles are apparent in all cases.

Quality

The placement and inspection processes ensure, when used in tandem, that the customer can be assured of optimum quality and reliability in their products at all times.

Unit Assembly

In many instances, assembly of the PCB is only part of the process. For many of our customers we also amalgamate the PCB assembly into higher levels of product. This may include wiring, cabling and mechanical assembly, the service for any and all of which we can and do provide...

Our ability to optimize this important part of the manufacturing process is due to our understanding of the finished product and in turn the end user.

A cornerstone of our philosophy is to ensure our customer satisfaction by maintaining and meeting their requirements.

As part of the materials management process, PSL can supply ancilliary items such as PSUs, cables, manuals and packaging to enable direct shipment from our facility to Point of Sale. We also provide a returns process for those customers that include either repair or reconfiguration as part of their requirements.

PCB Capabilities

Kitting & Materials Logistics

As part of our “One Stop Shop service” PSL can provide a comprehensive material supply package covering every aspect of component procurement, from hard-to-source one line items to full kit supply including bare boards...

Due to our broad base links to the materials supply infrastructure PSL can source components quickly and cost-effectively for an extremely wide range of end uses.

Whether your need is for PCBs, reeled components, complex devices or just hard to find parts, the team at PSL can assist.

ENGINEERING

The hub of any production facility is its production engineering department.

At PSL, production engineers are available to generate all aspects of the process paperwork, and tooling ensuring that the highest levels of quality and on-time delivery are met whilst endeavouring to maintain minimum cost.

We have the ability to generate all the process tools required for a wide range of customer needs from purely commercial to military applications, and our production engineering expertise ensures a fast but controlled response to both long and short term customer requirements.

Efficient tooling makes for efficient shopfloor processes and optimum product quality.

Design for Manufacture

The engineering staff at PSL can review existing or new products to optimize the production process, which in turn provides our customers with the most cost effective solution to their manufacturing needs...

Company personnel can convert existing through-hole assemblies into more state-of-the-art surface mount technology, again providing significant savings both in terms of cost and lead-time.

Irrespective of complexity, PSL can transform your new ideas into a cost effective addition to your product range. Is your product as easy to manufacture as the competitions? Here too we can help. Customer products can be assessed in term of ease of manufacture and recommendations made to ensure that all production activities are optimised.

Ease of manufacture goes hand in hand with fast reaction times and on time delivery. Small changes in layout or design can save you time and money by simplifying and speeding up the assembly process. PSL are experts at making these recommendations for our customers' advantage.

Controlled Storage

At PSL we have a 10,000 sq ft bonded storage facility, complete with all the processes required by cutting edge Electronic Assembly...

We have a moisture control area to cope with the millions of customer-supplied components awaiting assembly. We also have baking ovens and a vacuum sealer for any moisture sensitive devices. Our stores personnel are fully trained in component moisture sensitivity levels and keep records of time and temperatures of the components stored, if required.

Understanding the problems that may occur to components, and having adequate procedures in place to stop them happening, results in very high levels of first time pass rates on products tested at PSL or by the end customer.

All material is booked in using the customer-supplied BOM and any issues are passed on to the production manager where they can be resolved very quickly. This ensures the end customer always gets the quality products that they are expecting. Any shortages are identified and a shortage log is generated. This enables the production manager to liaise with the supplier or customer and to keep them updated on the production of their builds.

Free issued material is also controlled in this facility and customers are given their own locations, where the stock is controlled by the use of our cloud-based system. This allows remote access to the stock levels by the customer. Also, any returned kits are booked out and a record kept of the quantities returned to the customer.

We are very conscious of the costs of materials, and do all we can to make sure that once the material is here it is stored and handled within the correct parameters for the type of component that is to be stored.

surface mount Assembly

Based on state-of-the-art placement equipment, screen printers and reflow ovens, PSL can provide solutions to a wide range of surface mount scenarios...

Within our 9 lines we have a variety of pick-and-place machines, offering us complete flexibility of use, with sizes up to 1.5m in length on a single board and speeds of up to 140,000 placements per hour.

Surface mount, through hole / surface mount hybrids, fine pitch BGA, UBGA, Flexi, Flexi-Rigid, FR4, Ceramic and Metal substrate can be accommodated into our flexible manufacturing process.

Passive devices down to 01005, plus large fine pitch and BGA packages can be co-resident within the same assembly.

Front-end engineering provides the customer with hard copy verification that re-flow eutectics are within acceptable parameters and that components are not exposed to any form of detrimental thermal shock.

Process control is such that once the initial engineering work has been completed, the repeatability of parameters for on-going production batches is assured to as near as possible 100%.

Hand Assembly

Our assembly operators have a vast experience in all forms of PCB and Unit assembly covering both commercial and military products....

The workforce prides itself in its ability to provide extremely high levels of quality. This is achieved by the fact that each operator takes personal responsibility for attaining zero defects, and this coupled with a closed loop corrective action procedure that ensures any potential improvements to the assembly process are captured and implemented.

First off, and in-process inspection incorporating AOI ensures that manufacturing process errors are mimimized and that our high levels of quality are maintained.

PSL assembly operators can also action configuration changes, by way of modification, to existing products. These upgrades are of course to the same quality levels as any new assemblies.

FLOW SOLDER

One of the most important attributes of the modern day PWBA production factory is still Flow Solder...

The Blundell wavesolder equipment used at the facility is capable of accommodating conventional through hole assemblies as well as surface mount hybrids that conform to all aspects of ISO9001:2015.

Solder joint integrity and quality is recognised as one of the major cornerstones of any PCB based product and at PSL we pay great attention to detail in this area.

Appropriate levels of preventive maintenance ensure that equipment is performing at optimum efficiency.

Closed loop positive feedback from online quality control and test engineers maintain high levels of quality.

AOI

As a further aid to continuous quality improvement, PSL has added four Automatic Optical Inspection systems to its already impressive arsenal of equipment...

XY Data from any of the SMD placement machines can be fed to the AOI station and then used as a basis for a high speed SAKI BF-Voyager optical scan of the PCB assembly under review.

With its comprehensive, multi-level lighting and camera system, the MIRTEC can perform a wide range of inspection tasks with far greater levels of accuracy, speed and consistency than even the best human inspector.

Areas covered by the MIRTEC include:

- s/c detection

- dry joint/open circuit detection

- text recognition and hence component value/identity checks

- polarity/rotational checks

- component omission and placement accuracy checks

Because of the link to the surface mount assembly process, the AOI station can be almost instantaneously up to speed and on line, checking production of new products.

Test

Although we believe that our assembly processes provide the highest quality possible, we recognize that sometimes this is not enough. Customer perception is a very important aspect of the Contract Manufacturing Marketplace and a full test facility is available to support this...

We ensure that the testing process reflects the parameters and uses that the product will encounter in its working life as accurately as possible. This means every unit that leaves our facility will function to the specification laid down by the customer.

The test process can be PC-based or can utilize specific test equipment as specified by the customer.

Test results of all products are recorded and any failures correlated to be fed back into the assembly process via the corrective action system and ensure continuous improvement.

BGA Replacement

More and more design teams are taking advantage of the integration of function and reduced space requirement afforded by BGA packages. To this end, PSL can now offer a BGA placement and upgrade service for those customers who require this facility...

Using a PDR rework station PSL can now place, or replace, all forms of BGA footprint devices. The system ensures that both correct temperatures and eutectic curves are met when dealing with what can be expensive prototype or production parts.

BGA Inspection

Once placement or rework has been carried out, PSL can then use its Ersascope inspection station to review the solder joints beneath the devices to ensure that the correct alignment and 'double drop' profiles are apparent in all cases.

Quality

The placement and inspection processes ensure, when used in tandem, that the customer can be assured of optimum quality and reliability in their products at all times.

Unit Assembly

In many instances, assembly of the PCB is only part of the process. For many of our customers we also amalgamate the PCB assembly into higher levels of product. This may include wiring, cabling and mechanical assembly, the service for any and all of which we can and do provide...

Our ability to optimize this important part of the manufacturing process is due to our understanding of the finished product and in turn the end user.

A cornerstone of our philosophy is to ensure our customer satisfaction by maintaining and meeting their requirements.

As part of the materials management process, PSL can supply ancilliary items such as PSUs, cables, manuals and packaging to enable direct shipment from our facility to Point of Sale. We also provide a returns process for those customers that include either repair or reconfiguration as part of their requirements.

We want to work with you

sales@printsys.co.uk

sales@printsys.co.uk 01438 311 211

01438 311 211